The role of pallet wrapping machine repair in improving supply chain processes

Wiki Article

Typical Repair Issues With a Pallet Wrapping Equipment and Exactly How to Deal with Them

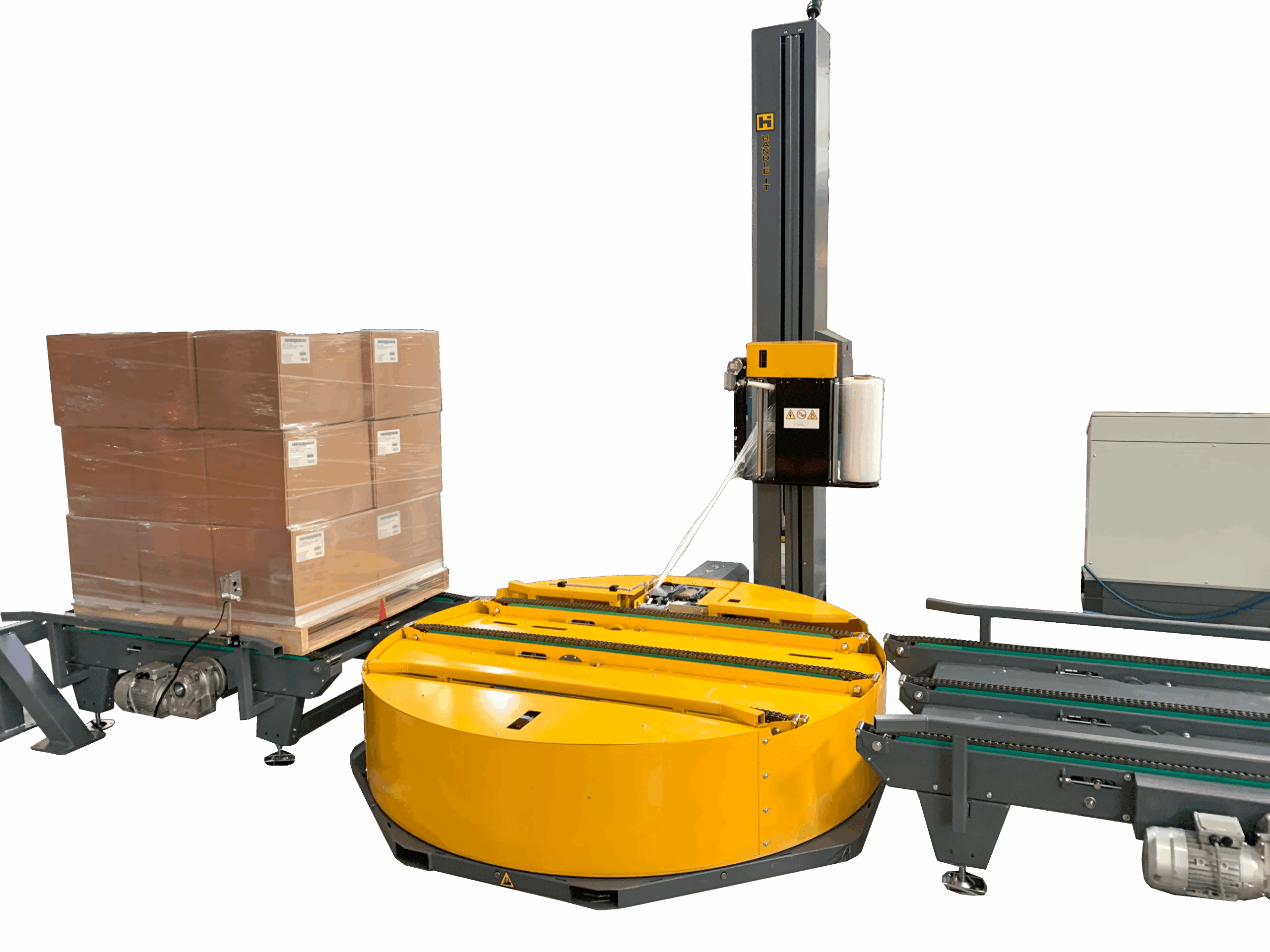

Pallet Wrapping devices are important in several industries for securing products. They often deal with typical fixing issues that can disrupt procedures. Inconsistent Film Tension, mechanical jams, faulty sensing units, and electrical troubles are just a couple of obstacles operators experience. Recognizing these concerns and their services can boost device performance and lower downtime. Resolving these troubles needs even more than simply standard expertise; it requires an organized strategy. What approaches can guarantee peak functionality?Inconsistent Film Tension

Inconsistent Film Tension can considerably influence the performance of pallet Wrapping equipments. When the Tension differs, it results in uneven Wrapping, which can jeopardize load stability and lead to item damage during transportation. Appropriate Film Tension is essential for preserving the honesty of the covered tons, as it ensures that the stretch Film sticks consistently around the pallets. Factors adding to inconsistent Tension include improper Film setup, worn-out components, or wrong device settings. Therefore, routine upkeep and adjustments are crucial in preventing these issues. Operators should be educated to keep an eye on the Film Tension continuously and make essential adjustments to the equipment setups as needed. Resolving these variances quickly can enhance the general performance and integrity of pallet Wrapping operations.

Mechanical Jams and Obstructions

Mechanical jams and obstructions can significantly disrupt the operation of pallet Wrapping devices, bring about enhanced downtime and minimized productivity. These concerns frequently develop from improper loading of pallets, twisted Film, or damaged components that fall short to operate efficiently. Normal upkeep, including the lubrication of relocating components, can aid protect against these complications. Operators must likewise validate that the Film is effectively lined up which there are no foreign things blocking the machine. Furthermore, routine assessments for deterioration can identify prospective issues before they rise into considerable breakdowns. By addressing these mechanical issues without delay, facilities can keep smoother procedures and lessen disruptions in the Wrapping procedure, ultimately improving total performance.Faulty Sensors and Controls

Film Damage or Poor Attachment

Film damage or inadequate attachment can significantly impede the effectiveness of pallet Wrapping procedures. These concerns usually originate from inappropriate Film Tension settings or making use of inappropriate Wrapping products. When the Film is too loose, it might not adhere properly to the lots, causing shifting or damages throughout transport. On the other hand, extreme Tension can cause Film breakage, triggering delays and extra material waste. Normal upkeep checks are vital to ensure that the Wrapping device's elements, such as rollers and Film dispensers, are working properly. pallet wrapping machine repair In addition, drivers should be trained to recognize signs of Film top quality damage and change setups as necessary. Attending to these concerns effectively can boost performance and minimize functional costs linked with film-related troubles.Electric Concerns and Power Failures

Reliability is essential in pallet Wrapping operations, as electric problems and power failings can disrupt performance and cause substantial downtime. Usual electrical problems include damaged electrical wiring, blown integrates, and malfunctioning control panels. These problems can frequently be mapped back to tear and wear or inappropriate upkeep. Routine examinations are vital to identify possible mistakes before they intensify. In addition, confirming that the machine is connected to a steady source of power can alleviate power failing threats. In instances of failure, fixing actions consist of checking connections, replacing integrates, and resetting the control panel. For consistent issues, seeking advice from a professional technician is a good idea to guarantee security and bring back capability effectively. Proactive treatment can greatly reduce the impact of electrical failures on operations.Frequently Asked Concerns

Just how Often Should I Perform Upkeep on My Pallet Wrapping Maker?

The frequency of maintenance for a pallet Wrapping machine generally depends on use. pallet wrapping machine repair. Routine examinations on a monthly basis, along with thorough maintenance every six months, can aid assure peak efficiency and durability of the devicesWhat Sort Of Film Works Ideal for My Particular Wrapping Requirements?

Identifying the most effective Film for specific Wrapping demands entails reviewing aspects such as tons weight, item type, and environmental problems. Different Film kinds, including stretch, shrink, and crossbreed, deal unique advantages customized to different applications.Can I Use Recycled Film in My Pallet Wrapping Maker?

Using recycled Film in pallet Wrapping machines is generally feasible, yet it may influence device performance and lots safety. Customers should assure compatibility and test the Film to prevent prospective issues throughout procedure.Just How Can I Improve the Efficiency of My Pallet Wrapping Refine?

To boost the effectiveness of the pallet Wrapping procedure, one need to maximize device setups, frequently maintain tools, train operators extensively, and examine workflow for possible bottlenecks, making sure smooth operation and taking full advantage of performance throughout the Wrapping cycle.What Safety Safety Measures Should I Take While Running the Equipment?

When running the machine, it is necessary to put on proper personal safety equipment, assure a clear work space, routinely examine safety features, and keep a secure distance from moving components to avoid injuries and crashes.

Inconsistent Film Tension can significantly impact the effectiveness of pallet Wrapping equipments. pallet wrapping machine repair. Correct Film Tension is essential for preserving the stability of the wrapped tons, as it ensures that the stretch Film adheres consistently around the pallets. Film breakage or poor bond can significantly prevent the performance of pallet Wrapping procedures. Regular maintenance checks are vital to ensure that the Wrapping device's parts, such as rollers and Film dispensers, are working correctly. The usage of recycled Film in pallet Wrapping machines is generally possible, but it may impact device efficiency and lots security

Report this wiki page